- High temperature acid concentration analyzer to protect waste heat recovery units from corrosion

Overview

Low temperature waste heat recovery technology has become the standard configuration of sulfuric acid plants. With the wide application of waste heat recovery devices in sulfuric acid plants, in the past two years, there have been several sets of waste heat recovery devices in China due to water, steam leakage or leakage of waste heat recovery devices have suffered serious corrosion. Due to the failure of the high temperature acid concentrator, the abnormal device was not found in time during the production operation, resulting in the waste heat recovery device to stop production for a long time and equipment damage, which brought huge economic losses to the enterprise. In order to avoid or reduce the occurrence of such incidents, this article will introduce how the high temperature acid concentration meter on the waste heat recovery device protects the safe operation of the device.

Part I Characteristics of low temperature waste heat recovery process

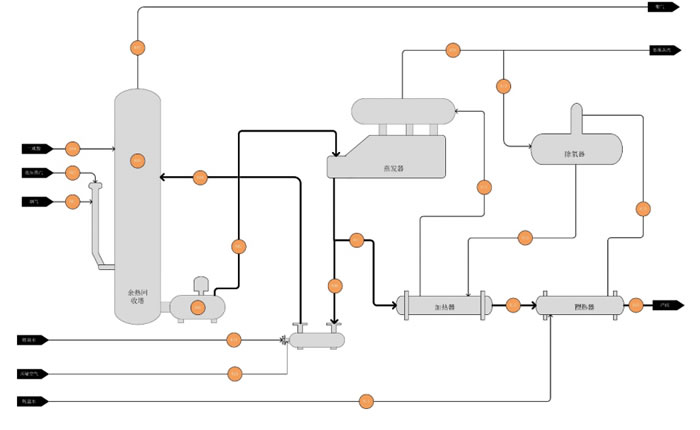

Low temperature waste heat recovery technology significantly reduces the need for circulating cold water in the acid process and improves the recovery efficiency of heat energy as much as possible. The working principle of the waste heat recovery device is to use the heat recovery tower to replace an absorption tower in the traditional process, and use the waste heat boiler to replace the acid cooler. The system is composed of waste heat recovery tower, acid circulation pump, waste heat boiler, diluter and heater. The waste heat recovery process diagram is shown in Figure 1. The control of the waste heat recovery plant is focused on adjusting the main process variables to minimize corrosion rates, reduce the formation of acid fog, and maximize the absorption and steam yield of SO3.

The

waste heat recovery process is characterized by operation at a high acid temperature, and the stainless steel equipment is exposed to high temperatures H2SO4. Therefore, the waste heat recovery device is more sensitive to process interference and requires more strict production control. The acid concentration is the core control point, and the process parameters (acid concentration, temperature) must be maintained within the normal operating range. The normal acid concentration range of the waste heat recovery process is 99.0% to 99.7%, and the temperature operating range should be lower than 227 ° C. The sulfuric acid concentration at the exit of the waste heat recovery tower should be lower than 99.7% to ensure effective absorption of SO3 in the absorption tower. In order to protect the stainless steel equipment in the waste heat recovery unit, the acid concentration at the primary entrance of the waste heat recovery tower (the diluter outlet) is usually not less than 99%.

Within the normal acid concentration and temperature operating range, the annual corrosion rate of the stainless steel material of the waste heat recovery device should be less than about 0.03 mm, if it is beyond the normal operating range, even if the time is very short, it may cause serious damage to the stainless steel equipment. The primary circulating acid concentration should not exceed 99.3% at any load, otherwise it will reduce the absorption rate of SO3. Similarly, it should not be lower than 99.0%, otherwise it will accelerate corrosion. Therefore, the acid concentration in operation is directly related to the safety of the waste heat recovery device.

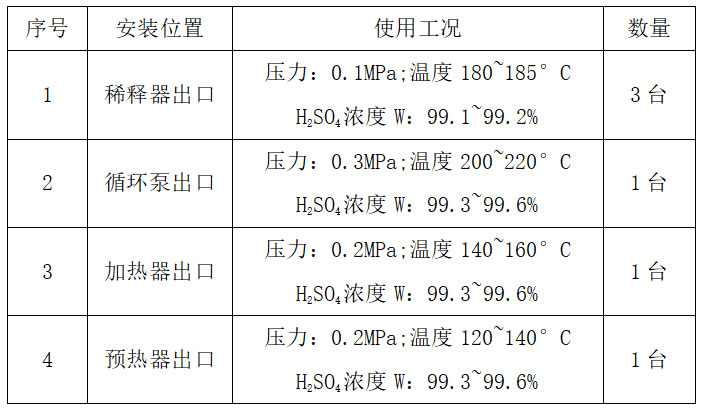

The second part of the acid concentration analyzer installation position

(1) diluter outlet

Three high temperature acid concentration analyzers were designed for measuring the outlet of the diluter. The specific measurement conditions are as follows:

- Pressure: 0.3MPa;

- Temperature: 180~185°C;

-H 2SO4 Concentration w: 99.1~99.3%.

The best control index is:

< p > -h < sub > 2 < / sub > SO < sub > 4 < / sub > w: concentration 99.15%, actual value deviation plus or minus 0.02% allowed.

This index not only ensures the best efficiency of the primary absorption process, but also protects the metal material of the waste heat recovery device from corrosion. In addition, it provides the necessary safe operating margin for the waste heat recovery unit when the load is adjusted.

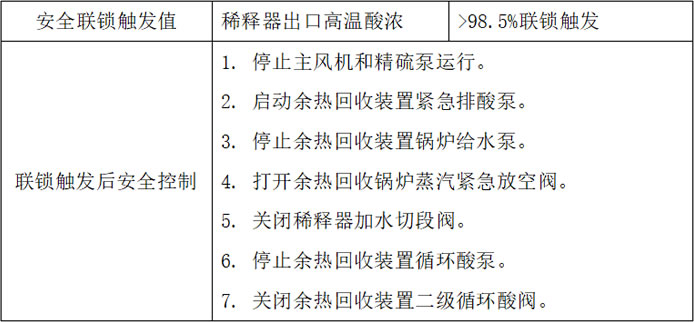

The core role of these analyzers is to monitor the concentration of sulfuric acid in the diluter during the water addition process to achieve automatic control. They are also responsible for monitoring the concentration of primary circulating acid to ensure that it does not exceed 98.5%, thus protecting the stainless steel equipment in the waste heat recovery unit from corrosion.

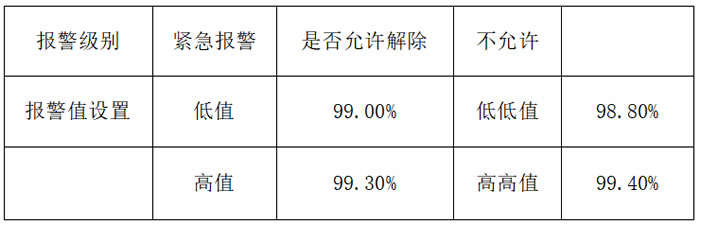

Safety control function: alarm

Interlock control Purpose:

When the sulfuric acid concentration control fails during the diluter water addition process, resulting in the sulfuric acid concentration in the primary cycle falling below the safety threshold, the safety interlock system will be triggered, causing the device to automatically stop and return to the safe state. This measure is designed to protect the device from severe corrosion and prevent the company from experiencing prolonged production disruptions.

Please note that since the sulfuric acid concentration of the waste heat recovery device is mainly controlled by adding water to the diluter, it becomes a key factor affecting the change of sulfuric acid concentration. Therefore, three high temperature sulfuric acid analyzers were designed at this key location, and a two-out-of-three intermediate value strategy was adopted to achieve automatic control of sulfuric acid concentration to ensure that the risk of serious corrosion of equipment caused by the failure of high temperature sulfuric acid analyzer was minimized. If any of the high temperature acid concentrators at the outlet of the diluter fail, they must be repaired within 4 hours. If two analyzers fail at the same time, do not remove the interlock. Manual analysis of the acid concentration at the outlet of the diluter should be performed every 30 minutes during meter repair. If the three acid concentration meters fail at the same time, they should be stopped immediately, and wait for the high-temperature sulfuric acid analyzer to return to normal before restarting. In the security interlock system, the interlock release function should not be set.

(2) Circulation pump outlet

High temperature sulfuric acid concentration analyzer at the outlet of circulating acid pump (design 1 high temperature sulfuric acid analyzer) for measuring the following conditions:

- Pressure: 0.3MPa;

- Temperature: 200~220° C;

-H 2SO4 Concentration w: 99.3~99.7%.

The best control index is:

-H 2SO4 Concentration w: 99.5%;

- Allowable deviation of actual value ± 0.05%.

This index not only ensures the best efficiency of the primary absorption process, but also ensures that the concentration of the primary acid is not less than 99.1%. In addition, it provides the necessary safe operating margin for the waste heat recovery unit when the load is adjusted.

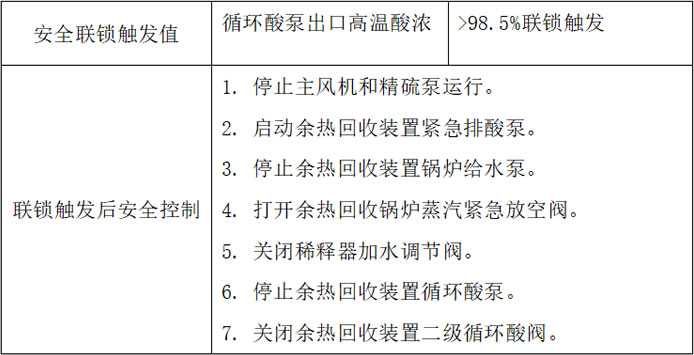

The core role of the analyzer is to monitor the concentration of circulating acid in the lower tower to ensure that it does not exceed 99.7%. This is done to ensure the absorption efficiency of the waste heat recovery tower and prevent the concentration of acid mist from exceeding the standard, so as to avoid corrosion of the heat exchanger.

In addition, the analyzer is used to monitor the presence of large-scale leaks inside the waste heat recovery unit for safety interlock protection against severe corrosion of the equipment.

Safety control function: alarm

Interlock control Purpose:

When there is a serious leak inside the sulfuric acid unit or the waste heat recovery unit, or the diluter water acid concentration control fails, resulting in the sulfuric acid concentration inside the waste heat recovery unit falling below the safe value, the safety interlock system will be triggered to shut down the unit and restore it to a safe state. This measure is designed to protect the device from major corrosion and prevent the company from shutting down for a long time.

Please note that in the event of a failure of the high temperature acid concentration meter at the outlet of the circulating acid pump, it must be repaired and restored to normal operation within 4 hours, during which time the interlock can be temporarily removed. During meter repair, the acid concentration at the outlet of the circulating pump should be manually analyzed every 30 minutes. At the same time, other safety interlocking measures of the waste heat recovery device shall not be removed.

(3) Heater outlet

Design a high temperature sulfuric acid analyzer for monitoring the sulfuric acid concentration at the heater outlet. The measuring conditions of the analyzer are as follows:

- Pressure: 0.2MPa

- Temperature: 140~160° C

< p > -h < sub > 2 < / sub > SO < sub > 4 < / sub > concentration w: 99.3 ~ 99.7% < / p >

Best control index To ensure that the sulfuric acid concentration at the heater outlet is consistent with the sulfuric acid concentration at the circulation pump outlet, the allowable deviation value is ± 0.1%.

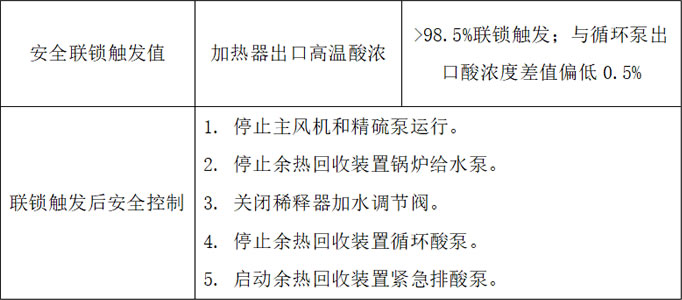

The core role of the analyzer is to monitor the heater for water leakage and as a safety interlock protection measure to prevent severe corrosion of the equipment.

Safety control function:

Alarm

Interlock control Purpose:

When a water leak occurs inside the heater, it can be quickly detected, and when the sulfuric acid concentration falls below the safe value, the safety interlock mechanism is triggered to stop the operation of the device and return to the safe state. The purpose of this is to protect subsequent equipment from serious corrosion.

Please note that in the event of a failure of the heater outlet high temperature acid concentrator, it must be repaired and restored to normal operation within 8 hours, during which time the interlock can be temporarily removed. Manual analysis of acid production from waste heat recovery should be performed every 60 minutes during meter repair. At the same time, be sure to keep the other safety interlocks of the waste heat recovery device active and shall not be lifted.

(4) Preheater outlet

Preheater outlet high temperature sulfuric acid concentration analyzer (design 1 high temperature sulfuric acid analyzer)

Measuring conditions:

Pressure: 0.2MPa;

Temperature: 110~140° C;

H2SO4 Concentration: 99.3~99.7%.

Best control index: Ensure that the H2SO4 concentration is consistent with the sulfuric acid concentration at the outlet of the circulating pump, and the allowable deviation value is ± 0.1%.

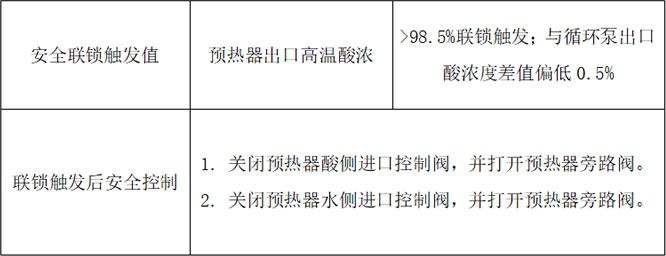

Core role: The analyzer is mainly used to monitor the presence of water leaks in the preheater, as well as to provide support for safety interlock protection equipment against severe corrosion.

Safety control function: alarm

Interlock control Purpose:

When water leakage occurs inside the preheater, it can be found in time that water leakage occurs in the preheater, and the safety interlock is triggered after the sulfuric acid concentration is lower than the safe value and is restored to the safe state. This protects the back-end equipment from severe corrosion.

Please note that once the high temperature acid concentrator at the outlet of the preheater fails, it must be repaired and restored to normal operation within 8 hours, during which time the interlock protection can be temporarily removed. During meter repair, manual analysis of acid from waste heat recovery should be performed every 60 minutes.