- High temperature acid concentration analyzer instructions

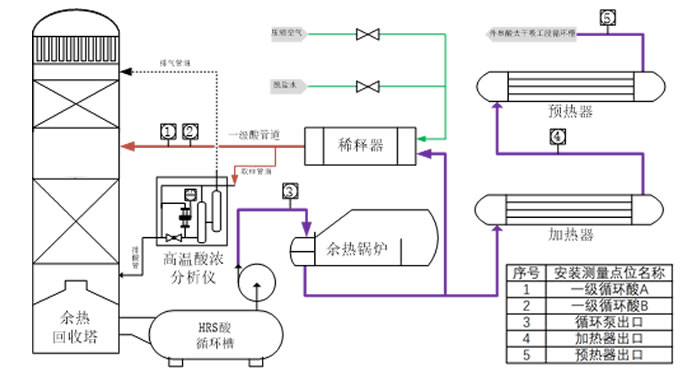

Diagram of high temperature acid concentration analyzer :

One, overview

High temperature acid concentration analyzer adopts gas-liquid rapid separation technology, which can obtain sulfuric acid concentration faster, provide accurate and stable acid concentration results for automatic control of diluter adding water, and also obtain the safety situation of heaters and preheaters faster; The whole body is made of 310 stainless steel material, corrosion resistance, long service life; Support a variety of conditions measurement use, such as waste heat recovery system (primary acid, circulating acid pump outlet, heater and preheater outlet acid concentration), dry suction system (dry acid, second acid, finished acid), electronic grade sulfuric acid production and other conditions of measurement, acid concentration analyzer measuring range of 96 ~ 100%, measuring temperature up to 220℃.

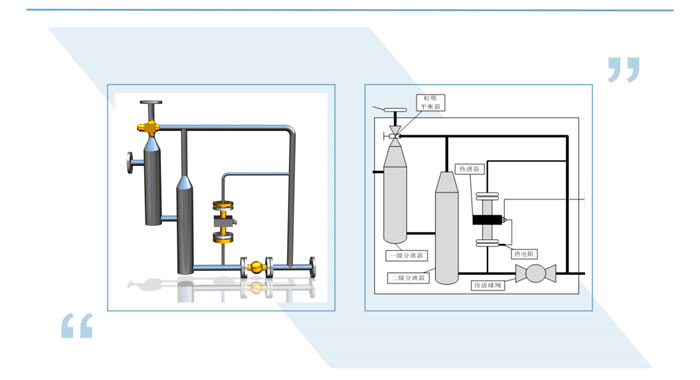

Gas-liquid separator Diagram of high temperature acid concentration analyzer:

Two, high temperature acid concentration analyzer safety precautions

The measuring medium of the high temperature acid concentration analyzer is high temperature concentrated sulfuric acid, the normal use temperature is 0 ~ 220℃, the concentration of sulfuric acid is 96 ~ 100%, and the maximum pressure is 1.6MPa; If the sulfuric acid temperature exceeds 220℃, the sensor lining will be damaged by tetrafluoride and the sealing gasket will leak. If the sulfuric acid concentration is lower than 96%, it will gradually corrode the gas-liquid separator of the high temperature acid concentration instrument. To ensure safe installation or maintenance, the operator must wear safety goggles, an acid mask, and an acid suit.

The high temperature acid concentration analyzer is in a high temperature state during use, and it is forbidden to touch the separator with your body; Do not loosen the connection flange and sensor flange during the use of the high temperature acid concentration analyzer; The gas-liquid separation flow channel inside the product is only 5mm, and particles are prohibited from entering the gas-liquid separator during installation.

Three, high temperature acid concentration analyzer installation steps and precautions

1. Remove the components of the high temperature acid concentration analyzer and check the contents in the box according to the contents of the packing list. If there is damage or missing, please consult the sales manager for inquiry.

2, check whether the high temperature acid concentration analyzer has the installation conditions, meet the following conditions to install:

The size standard of the process connection flange should be consistent with the size standard of the acid concentration analyzer flange, and ensure that all sealing surfaces should not be corroded or defective;

3, check whether the components of the complete set of equipment are missing, must ensure that the components are complete;

4, check whether there is foreign matter in the sulfuric acid inlet and outlet of the gas-liquid separator of the high temperature acid concentration instrument, if there is foreign matter, it will affect the normal use of the product;

5, Connect the sensor to the gas-liquid separator of the high temperature acid concentration instrument with the insulation component, if not, please replace it to ensure the long-term work of the conductivity sensor;

6, check whether the process flange connection of the conductivity sensor and discharge ball valve is tight, and whether the thermal resistance and temperature signal line are installed;

7, check whether there is sulfuric acid overflow or acid gas escape in the field process interface of the high temperature acid concentration instrument analyzer. Before installation, ensure that there is no sulfuric acid overflow or acid gas escape in the field process interface. If there is sulfuric acid overflow or acid gas escape, no installation is allowed.

8, the installation position of the high temperature acid concentration analyzer should avoid the walking channel, maintenance channel, emergency channel, cable bridge, etc., to prevent the leakage of the process connection flange of the high temperature acid concentration analyzer;

High temperature acid concentration analyzer Installation diagram of waste heat recovery system :

Four, high temperature acid concentration analyzer maintenance and overhaul

(1) During normal operation, observe whether there is acid mud at the connection of the sensor flange and whether the exhaust pipe is normal;

(2) Maintenance of high temperature acid concentration analyzer should be carried out by professionals in an open and stable position, and it is not appropriate to carry out maintenance work of high temperature acid concentration analyzer on the tower;

(3) When the conductivity sensor needs to be replaced or repaired, close the inlet isolation ball valve first, open the discharge ball valve to drain the sulfuric acid in the separator, wear acid-proof clothing, acid-proof glasses and heat insulation gloves, remove the thermal resistance, and finally remove the conductivity sensor;

(4) It is forbidden to tighten the bolts of the conductance sensor when the inlet isolation ball valve is not closed. When sulfuric acid oozes from the connection flange of the conductance sensor, it is necessary to close the inlet isolation valve, drain the sulfuric acid, clean the acid mud on the surface, remove the bolt of the insulation component of the sensor, and take off the conductance sensor to check whether the sealing surface of the mounting flange at both ends is corroded. If the sensor needs to be washed with clean water, the sulfuric acid on the sensor must be washed until the PH test paper rinse sensor water is neutral, and the gas-liquid separator of the high temperature acid concentration instrument cannot be cleaned with clean water to avoid dilute sulfuric acid splashing into the eyes, causing blindness;

(5) When reinstalling the conductivity sensor, check whether the insulation component is damaged. If the insulation sleeve, insulation gasket, and insulation bolt are damaged, replace them to ensure the connection between the installed conductivity sensor and the gas-liquid separator. After installation, the resistance of the sensor to the device is greater than 10M&Omega. ;

(6) The sulfuric acid device shutdown overhaul or the high-temperature acid concentration analyzer has been used for 1 year, it is recommended to replace the sensor insulation assembly and clean the acid mud in the gas-liquid separator, and it is also necessary to remove the screw rod of the siphon balancer to clean up the internal debris;

(7) The gas-liquid separator of the high temperature acid concentration instrument needs to be measured once a year.

Five, fault cause analysis and solution